المنتجات الساخنة

In-pit crushing and conveying technology in open-pit mining

网页In-Pit Crushing and Conveying (IPCC) systems are receiving more attention today due to current characteristics of open-pit mining operations and what is expected to occur in the

Contact

Comparison of fixed and mobile in-pit crushing and

网页2020年9月1日Truck-shovel and in-pit crushing and conveyor systems are two alternative systems. Discrete event simulation is a strong tool to compare two systems.

Contact

In-Pit Crushing and Conveying (IPCC) TAKRAF GmbH

网页In-Pit Crushing and Conveying (IPCC) systems cut truck haulage to a minimum and build operational resilience they substantially reduce operational expenditure (opex) and provide various other environmental

Contact

In-pit crushing and conveying systems changing the

网页2017年2月16日The purpose of an IPCC system is to allow the ore to be crushed in the pit and transported out using a conveyor system. In-pit crushers can be mobile which means they can be moved within days

Contact

In Pit Crushing and Conveying Systems 911 Metallurgist

网页2018年7月4日The essential task of the in-pit crusher in a belt conveyor transport system is to reduce blasted material to a conveyable size. Crushers for this purpose are almost exclusively of the low crushing ratio

Contact

Modelling of In-Pit Crusher Conveyor alternatives Taylor

网页This stone investigates alternative IPCC configurations for pre-stripping application in an open pit coal mine. It demonstrates that system redundancy in the form of introducing

Contact

Review of the in-pit crushing and conveying (IPCC

网页In-pit crushing and conveying is an alternative system for transport in open pit mines. Depending on individual parameters, it can achieve full or partial replacement of trucks

Contact

In pit crusher conveyour system SlideShare

网页IN PIT CRUSHER CONVEYOR SYSTEM: IPCC SYSTEM means In pit crusher conveyor system. IPCC system is also called as SEMI MOBILE CRUSHER. IPCC system crushing of overburden and coal inside the

Contact

In-pit crushing and conveying solutions

网页For example, crusher selection is a key discipline in introducing IPCC, but we also know that crusher selection is not the end of the story. Since we also deliver downstream solutions, we are familiar with the whole

Contact

In-Pit Crushing and Conveying (IPCC) TAKRAF GmbH

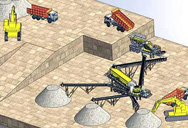

网页IPCC represents a viable, safer and less fossil fuel dependent alternative. A typical IPCC system comprises fully-mobile, semi-mobile or fixed in pit crushing stations connected to a network of conveyors and spreaders

Contact

In Pit Crushing and Conveying (IPCC) Systems BMT

网页Rio Tinto Clermont Mine in Central Queensland uses an In-Pit Crushing and Conveying System (IPCC) for a major component of its overburden stripping for the mine. The IPCC consists of a fully mobile sizing rig operating in

Contact

In-Pit Crushing and Conveying Terranova Technologies

网页A mobile crusher operating in a multiple-bench pit can feed a mobile Horizontal Conveyor with full-length receiving hopper. From here, material can be conveyed via Ramp Portables or via up-bench conveyors (each with Super Portable® technology) out of the pit and onto an overland conveying network.

Contact

Modelling of In-Pit Crusher Conveyor alternatives Taylor

网页In-Pit Crusher Conveyor (IPCC) systems offer advantages in the form of continuous operation, reduced labour requirements and decreased energy consumption resulting in lower cost per bank cubic metre. Nevertheless, IPCC systems are associated with high capital costs, lack of flexibility to adapt to changing mine plans and low effective system

Contact

(PDF) A comparison of strategic mine planning

网页2018年2月1日In pit crusher conveyor systems. Strategic mine planning. The system consists of a combination of loading the materials using excavators and feeding it into an in-pit crusher, crushing,

Contact

Aspects of in-pit crushing, conveying and dump layout

网页The increasing importance of the crusher/conveyor technology is shown with special regard to the hard rock open pit operations in South America. The economics of crusher/conveyor/spreader systems vs. truck transportation are highlighted and the requirements for introductions of conveyor systems are stated. The various crusher

Contact

SRK Publication Risks and Opportunities of Open-Pit Crushing

网页Category 1 Category 2 Category 3 Category 4. In suitable mining projects, in-pit crushing and conveying (IPCC) can provide operating cost reductions to the tune of 20 60% savings, depending on project specifics. For this reason, IPCC systems have been in use around the world for decades. IPCC systems consist of a primary crusher installed in

Contact

In pit crushing and conveying in surface mines

网页2019年12月30日Duval Corporation began installation of the first movable in-pit crushing and conveying systems in 1981 at its Sierrita Copper and Molybdenum Minenear Tucson, Arizona, and the operation of the system

Contact

In pit crusher conveyour system SlideShare

网页IN PIT CRUSHER CONVEYOR SYSTEM: IPCC SYSTEM means In pit crusher conveyor system. IPCC system is also called as SEMI MOBILE CRUSHER. IPCC system crushing of overburden and coal inside the

Contact

In-pit crushing and conveying solutions

网页For example, crusher selection is a key discipline in introducing IPCC, but we also know that crusher selection is not the end of the story. Since we also deliver downstream solutions, we are familiar with the whole

Contact

In-Pit Crushing and Conveying (IPCC) TAKRAF GmbH

网页IPCC represents a viable, safer and less fossil fuel dependent alternative. A typical IPCC system comprises fully-mobile, semi-mobile or fixed in pit crushing stations connected to a network of conveyors and spreaders

Contact

In Pit Crushing and Conveying (IPCC) Systems BMT

网页Rio Tinto Clermont Mine in Central Queensland uses an In-Pit Crushing and Conveying System (IPCC) for a major component of its overburden stripping for the mine. The IPCC consists of a fully mobile sizing rig operating in

Contact

A comparison of strategic mine planning approaches for in-pit

网页2018年3月1日The requirement for a fixed pit conveyor wall or slot means that pit expansion cannot take place where these are Knights P, Kizil MS, Nehring M. Selection and planning of fully mobile in-pit crusher and conveyor systems for deep open pit metalliferous applications. In: Proceedings of third international future mining

Contact

In-Pit Crushing and Conveying Terranova Technologies

网页A mobile crusher operating in a multiple-bench pit can feed a mobile Horizontal Conveyor with full-length receiving hopper. From here, material can be conveyed via Ramp Portables or via up-bench conveyors (each with Super Portable® technology) out of the pit and onto an overland conveying network.

Contact

Modelling of In-Pit Crusher Conveyor alternatives Taylor

网页In-Pit Crusher Conveyor (IPCC) systems offer advantages in the form of continuous operation, reduced labour requirements and decreased energy consumption resulting in lower cost per bank cubic metre. Nevertheless, IPCC systems are associated with high capital costs, lack of flexibility to adapt to changing mine plans and low effective system

Contact

Aspects of in-pit crushing, conveying and dump layout

网页The increasing importance of the crusher/conveyor technology is shown with special regard to the hard rock open pit operations in South America. The economics of crusher/conveyor/spreader systems vs. truck transportation are highlighted and the requirements for introductions of conveyor systems are stated. The various crusher

Contact

Review of In-pit Crusher Conveyor (IPCC) application

网页There are a few successfully documented cases of fully mobile crusher conveyor applications. To be economically feasible, semi-mobiel IPCC systems require productive reates on excess of 8000 tonnes per day in today's mining industry. In addition, conveyors start to gain an econmic advantage for transport distances of 5 km or more.

Contact

Modelling of In-Pit Crusher Conveyor alternatives

网页2013年12月1日In-Pit Crusher Conveyor (IPCC) systems offer advantages in the form of continuous operation, reduced labour requirements and decreased energy consumption resulting in lower cost per bank cubic metre. Nevertheless, IPCC systems are associated with high capital costs, lack of flexibility to adapt to changing mine plans and low effective

Contact

In-pit crusher location as a dynamic location problem

网页The conveying distance (or conveying costs) from in-pit crusher to an ex-pit destination is another factor that affects haulage costs. With the lower costs of conveyor transport compared to trucking, the in-pit crusher

Contact