المنتجات الساخنة

Feeder Breakers

网页The Feeder Breaker is an integral part of the material handling system, and reliably and consistently crushes and breaks down a wide range of material to precise

Contact

Grinding Mill an overview ScienceDirect Topics

网页Raw coal is fed to pulverizer from the coal feeder via a center feed pipe. The coal is grounded between the three grinding rollers and the rotating table in the pulverizer.

Contact

Coal Pulverizers an overview ScienceDirect Topics

网页Coal Pulverizers. Coal pulverizers have four separate processes, all of which can be impacted by coal characteristics: drying, grinding, classification, and transport. From:

Contact

Improving Coal Pulverizer Performance and Reliability

网页Coal Crusher Raw Coal Bunker To Boiler Furnace Raw Coal Feeder Exhauster Hot Air Motor Coal Pulverizer Figure 1: Simplified diagram detailing a direct-fired coal burning

Contact

The STOCK Gravimetric Feeder

网页typical pulverized-coal-fired unit fuel system consisted of storage bunkers holding two-inch or smaller sized coal, feeders to control the flow, pulverizers to dry and grind the coal to

Contact

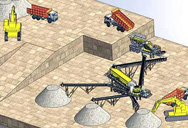

Coal Grinding Cement Plant Optimization

网页Elements of Coal Grinding System: Mill Feeding: Consists of following activities Coal Crusher: Generally, require when ball mill is used for grinding and raw coal size is on

Contact

The coal grinding

网页2017年7月11日Coal grinding is preparatory process to a creating mixture for combustion in boilers at thermal power plants. To a high-quality fuel creation for the TPP units furnaces (fuel has the coal basis), needs to

Contact

Coal Mill and Coal Feeders PDF Mill (Grinding)

网页Coal Feeders: Coal feeder is installed at the bottom of the coalcoal-bunker Capacity to supply coal (Range:7.4T/hr 43.6T/hr) Speed (Range:2.7 RPM 16RPM) Feed is

Contact

Pulverizer Wikipedia

网页Pulverizer. A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for combustion in the steam-generating furnaces of coal power plants .

Contact

Feeder Breakers

网页With a wide variety of feeder chain sizes, the smallest, a 1200 mm chain, can feed 1000 tonnes per hour, and the largest, a 2000 mm chain, can feed 2400 tonnes per hour. Fire suppression systems can also be fitted, and Feeder Breakers can also be converted or upgraded into a Feeder Breaker/Sizer combination if an in-section sizing solution is needed.

Contact

Flexible milling and grinding solutions that last

网页Optimal feed material milling and grinding solutions. Carefully crafted to meet your milling and grinding needs, our robust and well-designed solutions are highly adaptable for a range of feed materials. With

Contact

Grinding Mill an overview ScienceDirect Topics

网页Raw coal is fed to pulverizer from the coal feeder via a center feed pipe. The coal is grounded between the three grinding rollers and the rotating table in the pulverizer. Pulverized coal is simultaneously dried by the drying gas fed from bottom part of pulverizer and carried into the separator fixed at the top of pulverizer.

Contact

Gravimetricvolumetric feeder Schenck Process

网页Our volumetric feeders are the ideal choice for applications that require economic feeding solutions. Quickly assembled and dissembled, they are seamlessly integrated into existing production lines and easy to maintain. Additionally, our gravimetric feeders adjust feeding speed based on output demand, meaning your whole process is much more

Contact

Coal Pulverizers an overview ScienceDirect Topics

网页Raw coal is fed to pulverizer from the coal feeder via a center feed pipe. The coal is grounded between the three grinding rollers and the rotating table in the pulverizer. Pulverized coal is simultaneously dried by the drying gas fed from bottom part of pulverizer and carried into the separator fixed at the top of pulverizer.

Contact

Improving Coal Pulverizer Performance and Reliability

网页Grinding Action is carried out by aseries of hinged or fixed hammers revolving in an Improving Coal Pulverizer Bunker To Boiler Furnace Raw Coal Feeder Exhauster Hot Air Motor Coal Pulverizer Figure 1: Simplified diagram detailing a direct-fired coal burning system. 1 EPRI study on large coal fired utility boilers (greater than 600MW) using

Contact

The coal grinding

网页2017年7月11日The 40 mm grinding balls of the 2nd and the 3rd hardness groups have used for coal grinding at thermal power plants in USSR. The dust precipitated in the cyclone, poured into the hopper, then evenly

Contact

Coal Mill and Coal Feeders PDF Mill (Grinding) Industries

网页Presentation. On Maintenance of coal mill and coal feeders. Coal Mill Coal pulverizer pulverizer/mill /mill system: One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. mill.. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill. mill.

Contact

Improved Coal Feeding Control System of Thermal Power

网页initialization process, it is ready to start the coal feeder. If the coal feeder equipment is normal, start the coal feeder, if the equipment is abnormal, give an alarm and give a fault prompt. After the coal feeder starts and runs smoothly, the key parameters of the coal feeder are measured. If speed regulation is needed, the speed is

Contact

Pulverizer Wikipedia

网页Pulverizer. A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for combustion in the steam-generating furnaces of coal power plants .

Contact

Feeder Breakers

网页With a wide variety of feeder chain sizes, the smallest, a 1200 mm chain, can feed 1000 tonnes per hour, and the largest, a 2000 mm chain, can feed 2400 tonnes per hour. Fire suppression systems can also be fitted, and Feeder Breakers can also be converted or upgraded into a Feeder Breaker/Sizer combination if an in-section sizing solution is needed.

Contact

Flexible milling and grinding solutions that last

网页Optimal feed material milling and grinding solutions. Carefully crafted to meet your milling and grinding needs, our robust and well-designed solutions are highly adaptable for a range of feed materials. With

Contact

Gravimetricvolumetric feeder Schenck Process

网页Our volumetric feeders are the ideal choice for applications that require economic feeding solutions. Quickly assembled and dissembled, they are seamlessly integrated into existing production lines and easy to maintain. Additionally, our gravimetric feeders adjust feeding speed based on output demand, meaning your whole process is much more

Contact

Improving Coal Pulverizer Performance and Reliability

网页Grinding Action is carried out by aseries of hinged or fixed hammers revolving in an Improving Coal Pulverizer Bunker To Boiler Furnace Raw Coal Feeder Exhauster Hot Air Motor Coal Pulverizer Figure 1: Simplified diagram detailing a direct-fired coal burning system. 1 EPRI study on large coal fired utility boilers (greater than 600MW) using

Contact

Pulverizers 101: Part I POWER Magazine

网页2011年8月1日Pulverizers 101: Part I. Every coal pulverizer is designed with a particular fuel grinding capacity or throughput at a certain Hardgrove grindability index (HGI), based on a defined raw coal size

Contact

Hopper Discharge Systems Aumund

网页The arched plates of the feeder form a surface perfectly matching the drive and tail sprockets, hence allowing cleaning of the plates with a scraper. Fitted with a weighing rail and a frequency controlled drive unit, this conveyor may be used for proportional feeding of grinding units. Deep-Drawn Pan Conveyor type KZB-S The Deep-Drawn Pan

Contact

Feed Coal an overview ScienceDirect Topics

网页Grinding raw biomass is not only energy intensive but it is also difficult to obtain finer particle sizes in an adequate amount for a given energy input. Such high-energy requirement may be a result of the plastic behavior of biomass. 13.2.17 Loss of coal feeder. Loss of a coal feeder causes raw coal feed to associated puverizer to shut off.

Contact

The coal grinding

网页2017年7月11日The 40 mm grinding balls of the 2nd and the 3rd hardness groups have used for coal grinding at thermal power plants in USSR. The dust precipitated in the cyclone, poured into the hopper, then evenly

Contact

Improved Coal Feeding Control System of Thermal Power

网页initialization process, it is ready to start the coal feeder. If the coal feeder equipment is normal, start the coal feeder, if the equipment is abnormal, give an alarm and give a fault prompt. After the coal feeder starts and runs smoothly, the key parameters of the coal feeder are measured. If speed regulation is needed, the speed is

Contact